- Water Monitoring

- WATER MONITORS BY PARAMETER:

- WATER MONITORING PRODUCTS:

- EchoSmart Sludge Blanket Monitor

- FilterSmart Gravity Filter Backwash Monitor

- Q46N Dissolved Ammonia Monitor

- Q46H/62-63 Residual Chlorine Monitor

- Q46H/79PR Total Chlorine Monitor

- Q46H/65 Chlorine Dioxide Monitor

- Q46C2 2E Conductivity Monitor

- Q46C4 4E Conductivity Monitor

- Q46/84 Hydrogen Peroxide Monitor

- Q46D Dissolved Oxygen Monitor

- Q45D Dissolved Oxygen Transmitter

- Q46H/64 Dissolved Ozone Monitor

- Q46/85 Peracetic Acid Monitor

- Q46P/R pH & ORP Monitor

- Q45C2 2E Resistivity Transmitter

- Q46S/66 Residual Sulfite Monitor

- Q46/88 Suspended Solids Monitor

- Q46/76 Turbidity Monitor

- View More >

- SMART WATER SOLUTIONS

- Gas Monitoring

- GAS MONITORS BY PARAMETER:

- GAS MONITORING PRODUCTS:

- A12 2-Wire Toxic Gas Transmitter

- A12-17 Combustible Gas Detector

- A14/A11 Modular Gas Detector

- A21 Gas Sampler

- A23-14 Ozone Generator

- B12 2-Wire Gas Transmitter

- B12 Wet Gas Detector

- B14 Gas Alarm Module Receivers

- C12-17 Combustible Gas Detector

- C21 Dri-Gas Sampling System

- D12 Toxic and Combustible Gas Detector

- D12Ex-IR Infrared Gas Transmitter

- D16 PortaSens Portable Gas Leak Detector

- E12-15 IR High Level Ammonia Gas Detector

- F12D Toxic Gas Detector

- F12iS Toxic Gas Transmitter

- GasSens Midi Controller

- IsoMon Dual-Channel Gas Detection

- Q45S Wet H2S Gas Detector

- Industries

- Support

- News & Case Studies

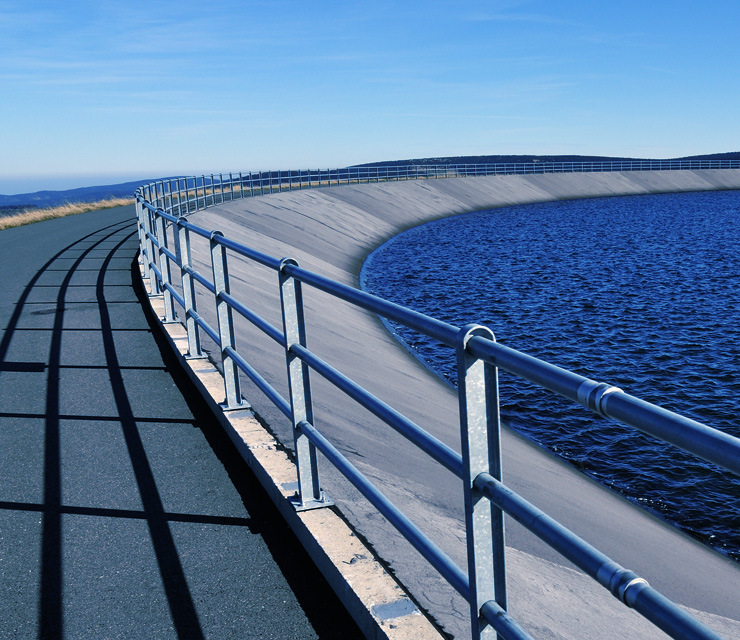

Currently in England and Wales governance of water quality is administered by the Drinking Water Inspectorate (DWI). The regulations at present stipulates multi parameter testing of the water quality at all service reservoirs in every water company in England and Wales once in a week. See reference below.

14.2 Regulation 14 [13] requires water companies to take a minimum of one sample from every service reservoir every week it is in use. These samples must be analysed for coliform bacteria, E.coli, colony counts and residual disinfectant. A week covers 7 days, inclusive, and if water is supplied from a reservoir at any time during a given week, then a regulatory compliance sample must be taken.

As many associated with the Water industry for any length of time will know, regulations in the industry change as modern technology advances and the ability to gather data drives more accurate and frequent monitoring. A case in point is pressure logging for reporting to the regulator, once done annually, it is now done with permanent pressure monitors at critical points.

Is it feasible that weekly reservoir sampling will remain unaltered when it can be monitored 24 hours a day and in real time if required? Is it also something that water companies should be content with, when now in the 21st century, we can learn so much by monitoring water quality at a reservoir site from inlets to outlets as live data or any intervals we wish to, and improve the customer experience?

The following are examples of reservoir monitoring. All tell a story and some of the examples are such as no serious issue requires attention. In fact, all the examples could be deemed as not requiring any actions, as before monitoring this was business as usual, but we were not aware of it.

It is fair to say that weekly samples would never show the profile of reservoir operation like the constant data does. And identifying potential risks or looking to operate reservoirs in a more efficient way would not be possible or at best guess work.

This reservoir has one inlet main, monitored by green data set. There are two outlet mains, one is a gravity outlet (brown data set) on the opposite side of the reservoir to the inlet and the other (red data set) is the suction pipework to a pump delivering to another reservoir. Issues here are:

It would be confusing if the weekly sample were from the pipe feeding the pumps as a variety of varying sample would give an inaccurate state of the chlorine in the reservoir.

Why is there such a difference in the two outlet chlorine levels? As the explanation on the graph shows the pump outlet is adjacent to the inlet main so therefore has less time to decay.

Where should the regulatory sample be taken from and what should be the target chlorine level be on which outlet? Some downstream system knowledge would be required for the effects on customers on each outlet.

Is there an issue with the red data in that the chlorine rises sharply but tapers of over a longer period of time? Understanding the pump running profile and the pipe work to the analyser itself indicates in this case, no issues.

The first reservoir in this example supplies the second reservoir. The outlet chlorine residual in the first reservoir is for the most part stable and would appear to show no real issues. The outlet flow is constant but increases when the pump station runs, when the second reservoir requires filling.

The pump running can be seen in that the residual, there, rises as the pump pulls water through it (the pump is 2 – 3 miles from the reservoir). The outlet residual at reservoir 1 drops when the pump runs, likely due to increased demand in reservoir 1 pulling in water from parts of the reservoir with less chlorine in it. It indicates that when the pumps are not running then there is a streaming from inlet to outlet within the reservoir, hence a very stable residual.

This is a cause of concern should the normal operation be interrupted, and the reservoir is called on to supply from its available storage which is likely to have reduced chlorine level in a significant percentage of this stored water.

The second reservoir is filled when the level drops and signals the pumps to run, also a mile or two away from the pumps. The issue of concern is that the reservoir back feeds the area between, pump and reservoir 2, when pumps are off.

This indicates customers are seeing a 0.2 variation in chlorine residual, this instability is not good, and some water companies prefer this not to happen.

The issue with reservoir two could be resolved by a significant length of new main for a dedicated inlet from pump to reservoir two.

It could also be resolved by abandoning reservoir two and converting the pumps to variable speed drives and running constantly, which would also make the flow out of reservoir one more consistent.

Reservoir one would benefit from reviewing the internal design and pipework of the reservoir to eliminate potential dead spots or significant percentages of lower quality water contained therein.

In this reservoir the outlet residual (brown data) is very stable with the exception of slight rises when the reservoir fills. The filling of the reservoir can be seen by the elevation of chlorine residual (red data). This reservoir is filled from an off-site pump and the chlorine dosing is at the pump site.

The fact that the outlet residual rises when the inflow starts indicates a short period of time before the outlet is affected. The fact that the elevation seen, on the outlet, is not significant and is not too different from when not filling, indicates a good travel inside the reservoir and consistent chlorine level for all the stored water contained.

In this case there is not an issue with the reservoir itself though if the rises and slopes were more significant it would indicate a need to investigate further the operation of this site.

The issue at this site, which is supported by other data not shown, is that when the pump is not running the outlet is cross connected to the inlet and supplies the main between pump and reservoir. So, the customers on the outlet see a consistent residual level but their neighbours on the inlet see a variable residual.

Due to the size and material of the mains and the dosing level at the pump site this variation of residual is quite severe. This is a good level of operation at the reservoir site but indicates that just looking in isolation can be misleading.

The example here indicates that some data can not be explained easily or can be misleading.

First the blue data is the post dose residual at the pump station filling the reservoir approximately half a kilometre from the reservoir. Dosing is simple flow proportional and this explains the drift in post dose, all be it slight, due to the incoming residual variation (this is exaggerated seasonally).

The sudden elevation on the blue line indicates the pumps starting and the dosing rig beginning to dose. The residual at the reservoir inlet has a parallel sudden increase, due to proximity, of the two sites. This is nothing unusual.

However, what can be seen is that when the dosing stops (sharp drop in blue line) the reservoir inlet (black line) does not drop and tapers off more slowly. Eventually dropping to nothing at times.

Although this looks very dramatic it is no cause for concern. What is occurring is purely connected to the flow to the analyser. The pressure in the main into the reservoir significantly drops when the pumps stop, and the analyser eventual losses all flow to it due to hydraulics in the sample line and main.

Most of ATi’s analyser housings today have an anti-syphoning design and this keeps the sensor wet, however the small amount of water can lose its chlorine level quickly. The amount of time between inflows is not enough to cause any adverse effect to the sensors. Though this looks dramatic, understanding the mains system and the positions of the sensors and site operation help determine there is no issues with this data (black line).

The outlet data (brown line) is variable and to some extent inconsistent. However due to no dramatic changes there is no urgent concerns while it remains like this. What this data shows is that it is not possible to explain every variation in a data set, and while on another site, this profile may indicate a problem, on this site it does not necessarily warrant concern or further investigation.

On the blue line post dose data there can be seen a slight blip in chlorine residual after the dosing stops, it drops and then slightly rises and then tapers of slowly until the next time the dosing starts. This could lead to thoughts of a problem; however, knowledge of the system and mains hydraulics can explain this data and can conclude there is no issues.

The reason is the dosing is at a pump site and the dosing stops at a pre set flow rate which is above zero flow, hence the pumps on slow down continue to pump a small amount of non-dosed water past the analyser sample take off, when the pumps stop completely there is some back flow created by the pressure in the main between pumps and the reservoir. Thus, the analyser begins to see some previously dosed water until dosing starts again.

The data above demonstrates how much can be gleaned from gathering just chlorine data at appropriate points at distribution sites. If so much can be determined from such little data, imagine what can be determined more accurately from other data on these sites

Conclusion

The examples above are not in themselves indicating major problems on sites that are a great need for concern. There are some needs to understand the sites and their relationship to other assets in the local system.

Not dealing with some of these examples could lead to a greater problem if left unattended. These sites are all independent of each other and do not effect any of the others, this however may not be the case in your distribution system and it is likely that gathering data from one site may not provide a satisfactory conclusion with out other sites data being available either before or after any given site.

The data above demonstrates how much can be gleaned from gathering just chlorine data at appropriate points at distribution sites. If so much can be determined from such little data, imagine what can be determined more accurately from other data on these sites such as flow, pressure and reservoir level and pump operation etc. Then add in other related network sites and assets also having several data sets.

Taking one (per week) sample batch of quality data from reservoirs gives very limited operational insight, especially if problems arise. There is no suggestion of not following regulatory guidance as other parameters are not always available for analysis by loggers and laboratory sampling is essential for determining the health of reservoirs. The two methods should complement each other.

Laboratory sampling however cannot determine operational issues as easily as permanent network sampling. Manual weekly sampling cannot be used so easily to determine developing trends or linked to warning alarms. They cannot determine if outlet issues are due to inlet supplies or within the reservoir. Permanent logging can assist in network modelling calibrations as trends and events may have useful time stamps.

The data above demonstrates that even reasonable data can indicate some need to dig below the surface it also demonstrates that after seeing data on a regular basis and understanding why its doing what it is and why the profile is like it is, we are better equipped for more serious issues that we see on other sites where the data profile is similar.

Featured Article

Reducing water scarcity with smart water solutions

In the UK there is growing concern that we could be heading for a future of increasing water scarcity, as the surge…

ReadA team of experts, ready to help

A global company with a caring culture. We have a team of experts on hand to help with any product or support query you may have. Contact us and experience ATi’s exemplary customer support.

Get in touch

Click here to see US contact details

Click here to see US contact details  Click here to see UK contact details

Click here to see UK contact details