Our smart water, source-to-tap solutions encompass flow measurement, water quality monitoring and data analytics. With products and solutions from Badger Meter, ATi and s::can, we have a comprehensive flow measurement and water quality monitoring offering that is transforming the water industry, enhancing how users manage their water systems.

With current and future communication and software technologies, we are creating robust digital solutions to help users turn data into actionable insights that drive better results, changing the way our customers collect, communicate, store and leverage data.

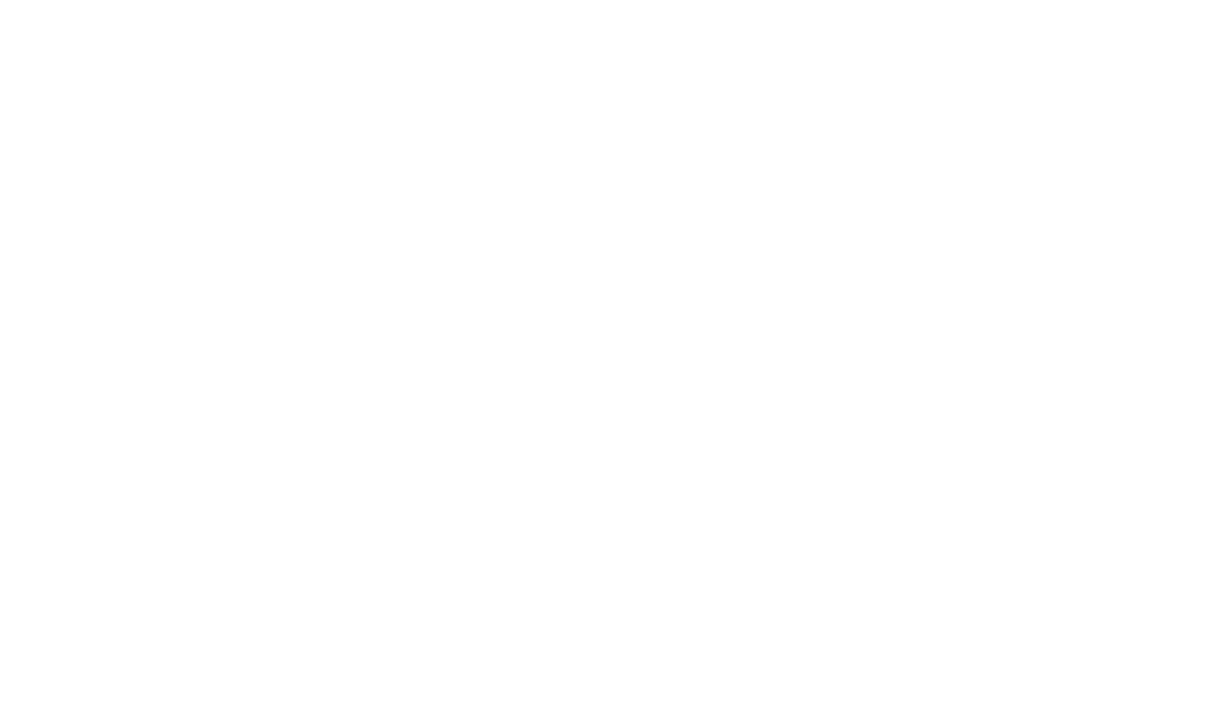

The below illustration shows how Badger Meter, along with ATi and s::can, can affect how you view, manage and control your distribution network. Our varied and technologically advanced product ranges allow us to have touchpoints across the entire network, including clean water and wastewater monitoring and measurement, through to Advanced Metering Analytics (AMA), cloud-based Software as a Service (SaaS) and cellular networks.

Network Solutions

Flow

Badger Meter ModMag Electromagnetic Flow Meter

Electromagnetic flow meters manage critical flow applications to improve accuracy, decrease system maintenance and meet the demands of challenging liquid conditions. This volumetric flow meter does not have any moving parts and is ideal for wastewater applications, or any dirty liquid that is conductive

or water-based.

Badger Meter Dynasonics & E-Series Ultrasonic Flow Meters

Ultrasonic flow meters are inferential meters that use ultrasonic technology to measure the velocity of an acoustically conductive liquid moving through it. There are two types of ultrasonic flow meter technologies, including Doppler & transit time. In addition to inline models, ultrasonic meters are available as clamp-on solutions, when contact with the measured fluid is not possible.

Water Quality

ATi MetriNet

Battery powered, continuous, real-time smart water quality monitoring from a choice of 16 ultra low powered, digital sensors. Delivering accurate, multi-parameter online data for proactive management of water quality in distribution networks.

ATi NephNet

NephNet online turbidity monitor is used to control both responsive flushing and controlled, planned cleaning, which helps to safeguard water quality for consumers. This technology offers a string of benefits to help water companies control their mains flushing, including continuous remote monitoring of turbidity, better accuracy at lower levels, fast connection to water mains via hydrants and wireless communications and alarms.

ATi SeptiNet

Designed specifically for applications in both wastewater treatment and sewer networks, SeptiNet generates continuous and accurate ORP and Hydrogen Sulfide (H2S) data for septicity prevention, allowing the management of odour and corrosion, whilst reducing the formation of hazardous atmospheres and negative environmental impacts.

ATi Q Series

The Q-Series range offers industry-leading monitoring solutions for over 20 parameters, trusted for the most demanding of clean and wastewater applications and used by water utilities globally. Our reagent-free water quality monitoring range offers a no-compromise approach to measurement in potable distribution, process and wastewater treatment, helping to drive down complaints, improve compliance ratings and reduce costs.

ATi FilterSmart

The FilterSmart Gravity Filter Backwash Monitor directly measures the parameters of actual interest: media expansion and turbidity. These two trends together present a clear picture of what’s going on during the backwash, allowing operators to ‘see’ into the process like never before.

During a backwash, the ultrasonic sensor tracks the level of the media and the turbidity sensor measures how clean or dirty the wash water is as it flows into the wash trough. These two measurements produce trends that together provide an extremely accurate profile of the backwash and become a powerful tool for optimising filter performance.

s::can pipe::scan

The pipe::scan is a modular sensor system for monitoring the quality of drinking water in pressurised pipes, measuring up to 10 parameters. The water quality data can be sent to any central database via almost any protocol.

s::can spectro::lyser

All spectrometer probes work according to the same principle: spectrometry. The s::can spectrometer probes are the first and only probes in the world that can measure optical spectra in the range of 190 to 720 nm directly in liquids. Substances contained in the liquid weaken a beam of light that is sent through it. A detector measures the light beam as it travels through the liquid and determines how much light has been absorbed.

s::can ammo::lyser

A multi-parameter probe for the online measurement of ammonium. A reliable device outclassing conventional analysers in terms of measurement stability and lifetime. Precision is guaranteed by real time compensation of the ammonium value, with temperature, pH and potassium and a high-performance reference electrode.

s::can micro::station

The s::can drinking water micro::station is designed for online monitoring of water quality parameters in clean media. The fully modular micro::station combines s::can instruments to a compact and versatile system. It presents a complete solution, as the user only has to connect water supply and discharge (plug & measure) to receive a previously unheard variety of immediately available information and parameters at no extra cost.

IoT

Badger Meter BEACON® Secure Cloud-Hosted Software Suite

The BEACON® Advanced Metering Analytics (AMA) cloud-based Software as a Service (SaaS) offers a utility management and consumer engagement solution to meet your meter reading, proactive exception management and reporting needs. The BEACON® AMA solution utilises our powerful ORION® endpoints to capture interval meter reading data through cellular, fixed network or mobile communication technologies.

Badger Meter ORION® Cellular Network

The ORION® Cellular endpoint is an evolution in AMI technology, strengthened by the Network as a Service (NaaS) approach. The innovative endpoint utilises existing IoT (Internet of Things) cellular infrastructure to efficiently and securely accomplish two-way communication of meter reading data via the LTE-M cellular network.

Badger Meter EyeOnWater®

EyeOnWater® web portal and native smartphone apps gives utility customers the power to manage their water use through easy-to-understand consumption graphs and configurable leak notifications, providing timely, visual access to their water usage behaviour. Personal water consumption data and the ability to create alerts for potential leaks means no need to wait for notification from the utility or a high water bill to take action.

Featured Article

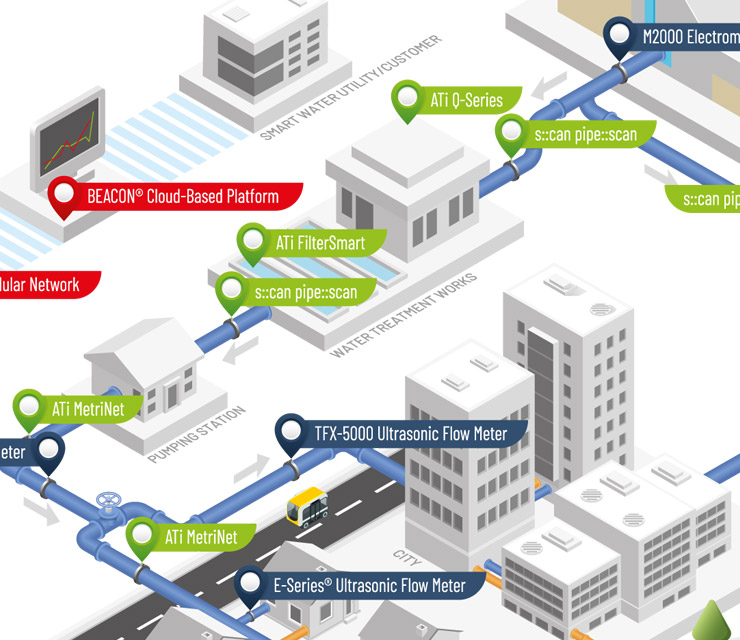

Analysing & evaluating service reservoir performance

Service reservoir performance analysis requires accurate and reliable monitoring, detailed understanding, and the expertise of a multi-disciplined team.

ReadA team of experts, ready to help

A global company with a caring culture. We have a team of experts on hand to help with any product or support query you may have. Contact us and experience ATi’s exemplary customer support.

Get in touch

Click here to see US contact details

Click here to see US contact details  Click here to see UK contact details

Click here to see UK contact details