- Water Monitoring

- WATER MONITORS BY PARAMETER:

- WATER MONITORING PRODUCTS:

- EchoSmart Sludge Blanket Monitor

- FilterSmart Gravity Filter Backwash Monitor

- Q46N Dissolved Ammonia Monitor

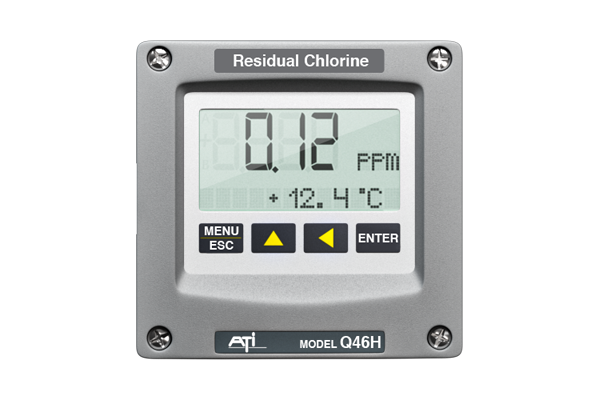

- Q46H/62-63 Residual Chlorine Monitor

- Q46H/79PR Total Chlorine Monitor

- Q46H/65 Chlorine Dioxide Monitor

- Q46C2 2E Conductivity Monitor

- Q46C4 4E Conductivity Monitor

- Q46/84 Hydrogen Peroxide Monitor

- Q46D Dissolved Oxygen Monitor

- Q45D Dissolved Oxygen Transmitter

- Q46H/64 Dissolved Ozone Monitor

- Q46/85 Peracetic Acid Monitor

- Q46P/R pH & ORP Monitor

- Q45C2 2E Resistivity Transmitter

- Q46S/66 Residual Sulfite Monitor

- Q46/88 Suspended Solids Monitor

- Q46/76 Turbidity Monitor

- View More

- Smart Water Solutions

- Gas Monitoring

- GAS MONITORS BY PARAMETER:

- GAS MONITORING PRODUCTS:

- A12 2-Wire Toxic Gas Transmitter

- A12-17 Combustible Gas Detector

- A14/A11 Modular Gas Detector

- A21 Gas Sampler

- A23-14 Ozone Generator

- B12 2-Wire Gas Transmitter

- B12 Wet Gas Detector

- B14 Gas Alarm Module Receivers

- C12-17 Combustible Gas Detector

- C21 Dri-Gas Sampling System

- D12 Toxic and Combustible Gas Detector

- D12Ex-IR Infrared Gas Transmitter

- D16 PortaSens Portable Gas Leak Detector

- E12-15 IR High Level Ammonia Gas Detector

- F12D Toxic Gas Detector

- F12iS Toxic Gas Transmitter

- GasSens Midi Controller

- IsoMon Dual-Channel Gas Detection

- Q45S Wet H2S Gas Detector

- Industries

- Support

- News & Case Studies

Chlorine residuals change during dosing and when the dosing equipment is paused, this is taken as normal operation within acceptable parameters. In this case study we want to explain what the real data examples can mean is happening at the local pipework and equipment close to the dosing point of application (POA).

Fig 1 is a typical POA on any main. There could be various combinations of this configuration such as, no pre dose analyser, no mixer if sufficient pipe lengths are available or a pump is doing the mixing. You may know of other options. The main may be before or after a reservoir, or a pump or simply in a trunk or distribution main directly into supply.

The position of the set up has its inherent problems and the consequences of the chlorine doing strange things has differing seriousness depending on this, as per the graph. It may also be that there are no consequences that need cause concern.

Fig 2 is real data, in this case from the inlet to a reservoir. The additional red and green lines are added examples but are true in nature and indicate real data from other sites. The Key should help us see when the flow starts and stops and the residual change and dosing set point. We will also see what happens when the rig is off that may cause problems and concerns, some of which in certain circumstances are not an issue.

Blue line = Chlorine residual, 1 – 2 = Residual decay in static water

1. The flow has stopped and the residual between points 1 and 2 slowly reduces over two periods of 6 or 7 hours each. This could happen for more than one reason.

• The flow to the cell containing the sensor has no flow to it and the static water is losing residual normally. The issue here is not the reducing residual but the flow to the cell if low level alarms are in place. Reasons of no flow to the cell will need investigating if alarms occur or there is to much lag in a good residual reading when flow re starts as this may affect initial dosing control.

• The flow to the cell is now from water in the main with only background residual and that chlorine content is slowly degrading. Issues are similar to the previous bullet point and again of little concern unless there are low level alarms that will shut the system down. If there is concern around having low alarms too low, then software and controls at the site will need refining.

Although the data is from a post dose monitor a similar thing can happen on a Pre-Dose analyser, if fitted. In most cases it is of little consequence and understanding why it is happening may be all that is required if no control or warnings are related to a pre-dose analyser. The exception to this would be with a feed forward dosing system.

2. At the end of the second 1 -2 period there is a small spike. There is also an added red line that indicates data that has been observed at other sites, of a far bigger spike. Why spikes occur like this whether large or small are likely to be for similar reasons. There are a few circumstances that can cause these. The consequences can be very different for the larger spike in comparison to the smaller one.

• The dosing lance is not a type that has a mechanism that inhibits Hypochlorite entering the main when the dosing is off. Due to drainage from the lance or line, as this is pressurised by the dosing pump.

• The mechanism in the lance for inhibiting lance/line drainage is not suitably adequate (due to pressure) or is in need of maintenance. Failure of other mechanisms in the dosing rig equipment may also contribute to this.

• The amount of hypochlorite within the end of the lance, after any self-closing mechanism, is enough to increase the residual at the local point in the main at POA All the above can be in part due to the pressure in the dosing line being greater than the resistance in an inhibiting device in the lance or a “loading valve” and or the mains pressure. There will almost always be some residue at the POA that will enter the main when dosing pumping stops.

This data and occurrences as indicated can have little or no detrimental effect. However, there can be some serious consequences suggesting some understanding of why this is occurring and if a resolution is required.

Usually this high residual is local to the mixer and pipework at the point of application and is a residual eventual seen due to travel within the local pipe. This is not usually harmful to customers as the high levels dissipate immediately the mains flow starts.

A high-level spike could cause a rig shut down, if the software controlling the rig, is set up that way.

Things to look at to resolve are, how much time passes before the spike appears, how high does it go, how long does it last and how quickly does it go when dosing re starts? There are likely other factors to consider too.

The consequences for a post dose analyser seeing these spikes may or may not be detrimental and investigation will determine this. However, should a similar thing occur on a pre dose analyser the consequences can be completely different. The causes and remedies will also be different.

The Green line spike example between the first 1 – 2 points on the graph is also indicative of the points above. However, though this may be due to a mechanical failure or lack of maintenance it may not be an easy fix if it continues.

With earlier examples a fix in the control software might get around this but this may not be so easy due to the time period covered when the elevation starts to occur. The solution may be a redesign in the dosing line / lance and POA. Each site will require its own evaluation for a solution.

Featured Article

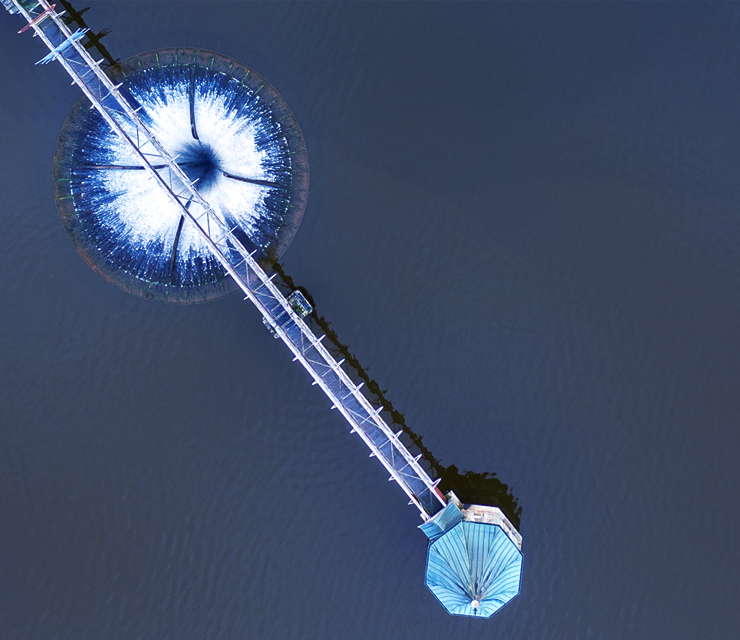

Non-interuptive reservoir water quality sampling

ATi recently worked in partnership with Panton McLeod and one of the UK’s largest water utilities, to facilitate a sampling survey…

ReadA team of experts, ready to help

A global company with a caring culture. We have a team of experts on hand to help with any product or support query you may have. Contact us and experience ATi’s exemplary customer support.

Get in touch

Click here to see US contact details

Click here to see US contact details  Click here to see UK contact details

Click here to see UK contact details