- Water Monitoring

- WATER MONITORS BY PARAMETER:

- WATER MONITORING PRODUCTS:

- EchoSmart Sludge Blanket Monitor

- FilterSmart Gravity Filter Backwash Monitor

- Q46N Dissolved Ammonia Monitor

- Q46H/62-63 Residual Chlorine Monitor

- Q46H/79PR Total Chlorine Monitor

- Q46H/65 Chlorine Dioxide Monitor

- Q46C2 2E Conductivity Monitor

- Q46C4 4E Conductivity Monitor

- Q46/84 Hydrogen Peroxide Monitor

- Q46D Dissolved Oxygen Monitor

- Q45D Dissolved Oxygen Transmitter

- Q46H/64 Dissolved Ozone Monitor

- Q46/85 Peracetic Acid Monitor

- Q46P/R pH & ORP Monitor

- Q45C2 2E Resistivity Transmitter

- Q46S/66 Residual Sulfite Monitor

- Q46/88 Suspended Solids Monitor

- Q46/76 Turbidity Monitor

- View More

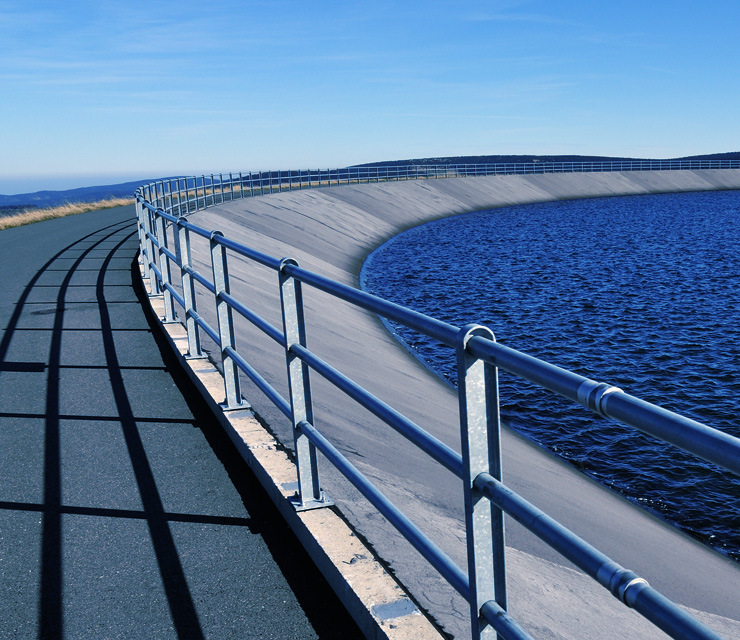

- Smart Water Solutions

- Gas Monitoring

- GAS MONITORS BY PARAMETER:

- GAS MONITORING PRODUCTS:

- A12 2-Wire Toxic Gas Transmitter

- A12-17 Combustible Gas Detector

- A14/A11 Modular Gas Detector

- A21 Gas Sampler

- A23-14 Ozone Generator

- B12 2-Wire Gas Transmitter

- B12 Wet Gas Detector

- B14 Gas Alarm Module Receivers

- C12-17 Combustible Gas Detector

- C21 Dri-Gas Sampling System

- D12 Toxic and Combustible Gas Detector

- D12Ex-IR Infrared Gas Transmitter

- D16 PortaSens Portable Gas Leak Detector

- E12-15 IR High Level Ammonia Gas Detector

- F12D Toxic Gas Detector

- F12iS Toxic Gas Transmitter

- GasSens Midi Controller

- IsoMon Dual-Channel Gas Detection

- Q45S Wet H2S Gas Detector

- Industries

- Support

- News & Case Studies

Maintaining a small amount of residual sulfite to control the removal of chlorine before discharge to the environment from clean water and also waste water effluent is common practice in many facilities.

Strongly reducing sulfur compounds such as SO2 gas, sodium sulfite or sodium bisulfite solutions are used to eliminate chlorine residuals that might prove toxic to fish and other wildlife in the receiving streams or rivers.

However, because residual chlorine discharge limits are often very close to zero, water quality monitoring residual values to comply with regulations has become very difficult and controlling residuals at values between zero and 10 or 20 parts-per-billion is often not achievable.

To meet stringent discharge limits, the sulfite or bisulfite used for de-chlorination is added in slight excess, providing a small sulfite residual to ensure complete de-chlorination.

This excess must be carefully controlled and monitored and ATi’s Q46S/66 provides operators with a reliable tool for maintaining a small sulfite residual while reducing excess chemical consumption due to overfeed.

Theory of operation

Because measuring the SO3= ion in solution is relatively difficult, the Q46S/66 Residual Sulfite monitor takes a different approach to the measurement, employing a unique gas-phase method to continuously monitor sulfite without contact between the sensor and the water sample, eliminating the potential for sensor fouling, plus the risk of formation of H2S on the GAC filters is reduced.

In operation, a small amount of sample is pumped into the system and mixed with acid. In acidic solution, the sulfite ion is converted to sulfur dioxide gas as follows:

SO3= + 2H+ → SO2 + H2O

The mixed sample flows into a special chamber where the sulfur dioxide is stripped from the sample. A gas conditioning module prepares the gas sample for measurement prior to contact with a special SO2 gas sensor designed for the system. Sensor signals are amplified and displayed on a large-format, backlit LCD display in the Q46S Residual Sulfite monitor electronics unit.

Maintenance

Sulfite monitoring systems are extremely easy to operate and maintain, with acid usage of one gallon/4.5 litres every 25 days at standard flow rates. Sample and acid are pumped using long life peristaltic pump tubing that requires replacement approximately every 6 months.

Pump heads are designed for easy tube changes, requiring about 10 minutes to replace both pump tubes. The sulfite sensor requires no maintenance other than an occasional visual inspection to ensure that no deposits have collected due to airborne particulates.

The gas stripping technique for monitoring sulfite in solution provides an extremely sensitive on-line monitor. Measurements down to low parts-per-billion can be done easily, and zero and span stability inherent in the sensor allow for monthly calibration cycles.

Chemical savings

Maintaining a small sulfite residual in dechlorinated water has the benefit of insuring complete de-chlorination. Monitoring the concentration of this residual allows chemical feed control that can result in significant chemical cost savings. The best way to look at potential chemical savings is to calculate the cost of each PPM of residual sulfite in a specific volume of de-chlorinated water.

Features

Sulfite Measurement

Sulfite ion is measured selectively by conversion to sulfur dioxide.

Gas Phase Sensing

Measurement is made without contact between sample and sensor, eliminating the potential for sensor fouling.

Chemistry Module Power Options

Power options include 115 or 230 VAC, 50/60 Hz.

Three Control Relays

Relays are programmable for setpoint, deadband, and time delay.

Sample Line Cleaning

Internal sequencing and relay system for automated sample line cleaning.

Digital Communication

Communication options for Profibus-DP, Modbus-RTU, or Ethernet-IP.

Featured Article

Chlorine spikes and what they can tell us

Chlorine residuals change during dosing and when the dosing equipment is paused, this is taken as normal operation…

ReadA team of experts, ready to help

A global company with a caring culture. We have a team of experts on hand to help with any product or support query you may have. Contact us and experience ATi’s exemplary customer support.

Get in touch

Click here to see US contact details

Click here to see US contact details  Click here to see UK contact details

Click here to see UK contact details