- Water Monitoring

- WATER MONITORS BY PARAMETER:

- WATER MONITORING PRODUCTS:

- EchoSmart Sludge Blanket Monitor

- FilterSmart Gravity Filter Backwash Monitor

- Q46N Dissolved Ammonia Monitor

- Q46H/62-63 Residual Chlorine Monitor

- Q46H/79PR Total Chlorine Monitor

- Q46H/65 Chlorine Dioxide Monitor

- Q46C2 2E Conductivity Monitor

- Q46C4 4E Conductivity Monitor

- Q46/84 Hydrogen Peroxide Monitor

- Q46D Dissolved Oxygen Monitor

- Q45D Dissolved Oxygen Transmitter

- Q46H/64 Dissolved Ozone Monitor

- Q46/85 Peracetic Acid Monitor

- Q46P/R pH & ORP Monitor

- Q45C2 2E Resistivity Transmitter

- Q46S/66 Residual Sulfite Monitor

- Q46/88 Suspended Solids Monitor

- Q46/76 Turbidity Monitor

- View More >

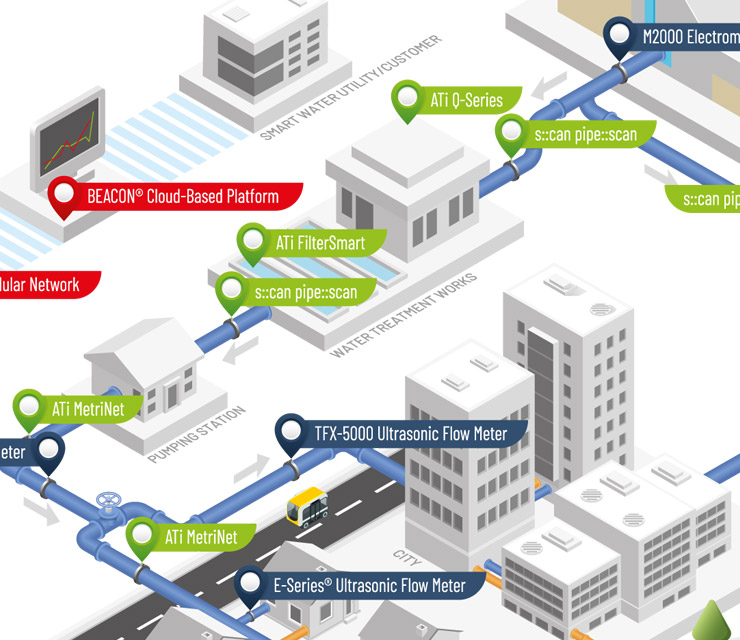

- SMART WATER SOLUTIONS

- Gas Monitoring

- GAS MONITORS BY PARAMETER:

- GAS MONITORING PRODUCTS:

- A12 2-Wire Toxic Gas Transmitter

- A12-17 Combustible Gas Detector

- A14/A11 Modular Gas Detector

- A21 Gas Sampler

- A23-14 Ozone Generator

- B12 2-Wire Gas Transmitter

- B12 Wet Gas Detector

- B14 Gas Alarm Module Receivers

- C12-17 Combustible Gas Detector

- C21 Dri-Gas Sampling System

- D12 Toxic and Combustible Gas Detector

- D12Ex-IR Infrared Gas Transmitter

- D16 PortaSens Portable Gas Leak Detector

- E12-15 IR High Level Ammonia Gas Detector

- F12D Toxic Gas Detector

- F12iS Toxic Gas Transmitter

- GasSens Midi Controller

- IsoMon Dual-Channel Gas Detection

- Q45S Wet H2S Gas Detector

- Industries

- Support

- News & Case Studies

Gas detection is crucial within the healthcare and pharmaceutical industries, particularly to ensure compliance with health and safety regulations during reprocessing of medical devices.

Peracetic Acid (PAA) decontamination procedures are essential for the disinfection of rooms and equipment to help infection prevention and control. However, concerns are on the increase over exposure to background levels of this sterilant used for disinfection. This high-strength oxidant is dangerous to all living cells, so how can it be proven that no toxic gases remain, eliminating serious health risks of keyworkers and patients?

ATi are one of the very few manufacturers in the world that can make an accurate sensor specifically to monitor PAA that can be used to protect staff. Our electrochemistry and sensor design expertise provides proven, reliable technology to ensure the safety of staff working where there is a risk of PAA exposure. This toxic gas detection solution provides hospitals with peace of mind that the health & safety of staff are continuously protected, by sending visual and audible alerts if limits are exceeded.

As part of the drive to protect staff and monitor the residual levels of PAA, one of our most recent projects saw ATi (a Badger Meter brand) join forces with NeQis Independent Monitoring Solutions on a project to deliver continuous monitoring instrumentation within hospital endoscopy environments that detects and reports on PAA levels during cleaning and disinfection processes.

Discover more about ATi’s expertise in providing Peracetic Acid monitoring solutions with the F12D fixed gas detector.

Monitoring background levels of Peracetic Acid

PAA is released into the air during reprocessing and should be monitored as part of your Quality Controls Program. Monitoring for chemicals, such as PAA, enables you to effectively manage the breathing environment. This continuous monitoring allows you to validate that the vapour in the air is safe, is generating the right amount of gas for efficacy and can also be used to demonstrate and prove that staff are at no risk when working in these potentially hazardous areas. Medical instruments, such as endoscopes, can be re-processed multiple times per day with high levels of PAA. It is therefore essential to understand and to monitor PAA vapour levels.

The Health and Safety Executive (HSE) states that ‘The Control of Substances Hazardous to Health Regulations 2002 (COSHH) requires employers to prevent or control exposure to hazardous substances. Where exposure cannot be prevented, employers are required to assess the risk to health, and provide adequate control measures when using hazardous chemicals.’

Smart sensor technology

ATi’s smart sensor technology provides an essential solution to ensuring staff safety within healthcare facilities, acting as an early warning system for staff well-being, with visual and audible alerts triggered when safe limits are exceeded.

The class-leading fixed F12D Toxic Gas Detector with PAA sensor plays an integral part in minimising risks, decreasing downtime and enhancing staff confidence and wellbeing by continuously monitoring and reporting on PAA levels. The F12D monitor is a continuous detector that can be positioned anywhere in a room to alarm when safe limits are hit. The system uses a pre-calibrated ‘vapour’ sensor that requires an annual replacement with no calibration vastly reducing staff intervention. The fixed monitor has a built-in data logging facility for historical data capture which can then be used to prove or disprove claims of exposure. The system gives ‘peace of mind’ to the health & safety staff that all stakeholders are protected with alerts or if limits are exceeded.

The benefits of using ATi peracetic acid smart sensor technology:

- ATi manufactured, interchangeable sensors for quick replacement

- Pre-calibrated ‘vapour’ sensor with full certification

- Annual replacement with no calibration reduces staff responsibility

- Visual and audible alerts when limits are met

- Reduces the need for a costly and time-consuming maintenance schedule

- Built-in data logging facility for historical data capture

- Acts as an early warning system for staff well-being

- Same sensor technology used in ATi’s fixed and portable monitors

- Accurate and reliable sensors proven through years of industry experience

- Cost-effective solution offering complete peace of mind

- Access to ATi’s award winning customer support

Risks of Over-Exposure

The high reactivity of PAA that underlies its benefits also means that excessive exposure to the vapour can be harmful and can cause health issues. Health risks due to exposure of PAA include:

- Permanent damage to lungs / pulmonary edema

- Permanent damage to eyes/sight

- Damage to ‘mucous membranes’

- Burns to skin

Peracetic Acid Exposure Guideline Levels

The Health and Safety Executive (HSE) states that ‘The Control of Substances Hazardous to Health Regulations 2002 (COSHH) requires employers to prevent or control exposure to hazardous substances. Where exposure cannot be prevented, employers are required to assess the risk to health, and provide adequate control measures when using hazardous chemicals.’

Links

ATi UK_Perfusionist White Paper_PAA.pdf

www.neqis.co.uk/wp-content/uploads/2022/02/NeQis-PACmon-Literature.pdf

References: Environmental Protection Agency:

www.epa.gov/oppt/aegl/pubs/results80.htm

Featured Article

Toxicity monitoring with AutoTest for Chlorine gas

Intelligent gas detectors play a vital safety role in areas where staff are routinely present, offering protection from…

ReadA team of experts, ready to help

A global company with a caring culture. We have a team of experts on hand to help with any product or support query you may have. Contact us and experience ATi’s exemplary customer support.

Get in touch

Click here to see US contact details

Click here to see US contact details  Click here to see UK contact details

Click here to see UK contact details