- Water Monitoring

- WATER MONITORS BY PARAMETER:

- WATER MONITORING PRODUCTS:

- EchoSmart Sludge Blanket Monitor

- FilterSmart Gravity Filter Backwash Monitor

- Q46N Dissolved Ammonia Monitor

- Q46H/62-63 Residual Chlorine Monitor

- Q46H/79PR Total Chlorine Monitor

- Q46H/65 Chlorine Dioxide Monitor

- Q46C2 2E Conductivity Monitor

- Q46C4 4E Conductivity Monitor

- Q46/84 Hydrogen Peroxide Monitor

- Q46D Dissolved Oxygen Monitor

- Q45D Dissolved Oxygen Transmitter

- Q46H/64 Dissolved Ozone Monitor

- Q46/85 Peracetic Acid Monitor

- Q46P/R pH & ORP Monitor

- Q45C2 2E Resistivity Transmitter

- Q46S/66 Residual Sulfite Monitor

- Q46/88 Suspended Solids Monitor

- Q46/76 Turbidity Monitor

- View More >

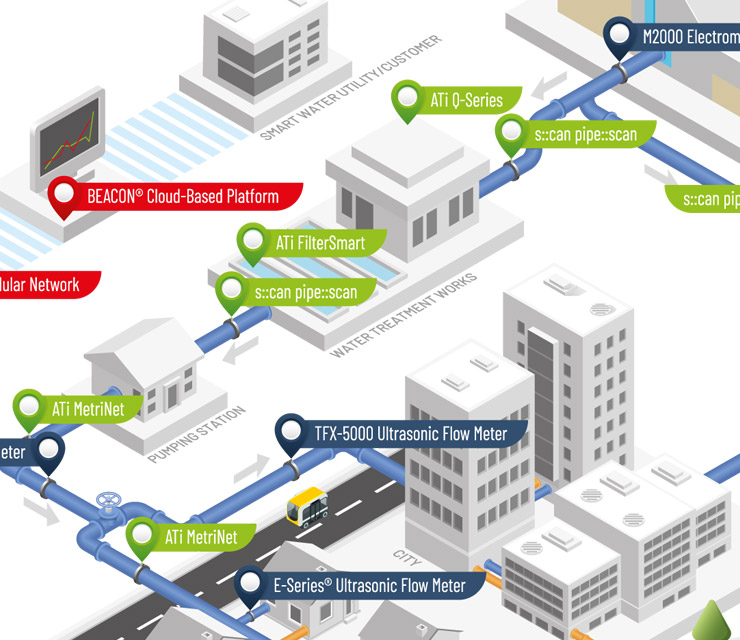

- SMART WATER SOLUTIONS

- Gas Monitoring

- GAS MONITORS BY PARAMETER:

- GAS MONITORING PRODUCTS:

- A12 2-Wire Toxic Gas Transmitter

- A12-17 Combustible Gas Detector

- A14/A11 Modular Gas Detector

- A21 Gas Sampler

- A23-14 Ozone Generator

- B12 2-Wire Gas Transmitter

- B12 Wet Gas Detector

- B14 Gas Alarm Module Receivers

- C12-17 Combustible Gas Detector

- C21 Dri-Gas Sampling System

- D12 Toxic and Combustible Gas Detector

- D12Ex-IR Infrared Gas Transmitter

- D16 PortaSens Portable Gas Leak Detector

- E12-15 IR High Level Ammonia Gas Detector

- F12D Toxic Gas Detector

- F12iS Toxic Gas Transmitter

- GasSens Midi Controller

- IsoMon Dual-Channel Gas Detection

- Q45S Wet H2S Gas Detector

- Industries

- Support

- News & Case Studies

The composition and concentration of sludge varies throughout the treatment pathway, therefore understanding the settling characteristics is vital to optimise control of both the plant and wastewater process. ATi’s Senior Service Engineer, Mark Holmes, discusses how the measurement of sludge levels with contactless, ultrasonic monitoring technology enables operators to study the sedimentation characteristics of suspended solids, understand sensitivities due to disturbances and manage sludge levels, whilst allowing sufficient buffering for incoming hydraulic load variations.

Measuring and managing the depth of sludge blanket is one of the most critical challenges in the production of good-quality effluent from wastewater treatment plants. Aside from lessening the environmental impact of human waste, modern plants have embraced advances in science and technology that allow significant, positive inputs, such as producing energy from biogases and in some cases generating revenue streams from processed biosolids, including nutrient-rich fertiliser for farming. However, for these advanced systems to work effectively, one of the most important parameters plant operators must monitor is total solids, or sludge, as it moves through the plant.

Effective automation to improve process control

Primary sedimentation, biological stages, secondary treatment, effluent quality and subsequent sludge handling are all greatly affected by how well the settling has been achieved and, crucially, monitored. By measuring sludge levels in both primary and secondary sedimentation tanks, operators can ensure sludge extraction pumps are used efficiently, while ensuring poorly settled sludge does not carry over into effluent paths.

While no two wastewater treatment plants are identical, the push to improve efficiency through automation and improved process control is a common theme. Relying solely on manual sampling means that thorough analysis of plant characteristics and trends is limited to the frequency of sampling, with the addition of labour costs. In a plant with continuous, automatic measurement of critical process variables, there is a wealth of data that creates a robustness of system control, capable of rapidly identifying disturbances or operational problems.

24/7 contactless sludge blanket level measurement

For measuring the depth of sludge blanket, the contactless method is considered the most desirable, as it doesn’t depend on direct measurement by human operation. ATi’s EchoSmart leading sludge blanket level monitor is trusted by water utilities across the globe, due to its superior sludge level detection for a wide range of water and wastewater applications, and monitors blanket levels 24/7, 365 days of the year. This underwater interface level analyser technology is built on a digital platform and allows the analyser to be located in the sensor. The result is greater flexibility in equipment configuration options, enhanced communication capabilities and reduced installation costs

The EchoSmart sensor generates an ultrasonic sound wave that propagates through a liquid medium and is reflected back from material that is present in the vessel, which are typically settled solids, suspended solids, or the tank bottom. The sound wave travels at known velocities, providing the ability to convert elapsed time into Range and Level measurements, offering continuous, real-time measurement. The underwater acoustic measurement principle allows the sensor to track well settled blankets, as well as being configured to track dispersed solids, such as ‘fluff’ or ‘rag-layer’.

Smart sensor technology

However, the EchoSmart sensor does more than just produce a raw signal. It is also equipped with an advanced programmable microprocessor and dynamic memory, with the sensors employing interface-detection algorithms developed exclusively by ATi. The smart sensor technology allows for field networks of sensors, enabling the control and monitoring of up to 16 smart sensors from one controller, which lowers the ‘per-tank’ cost. These field networks can also be created wirelessly, eliminating costly conduit and cabling runs.

Three sensor models provide flexible options for different applications: the standard sensor with multi-flex assembly for when surface skimmers are present; the self-cleaning sensor for applications without surface skimmers; and uniquely, a sensor with turbidity that offers further insight into water clarity, which is useful for less dense blankets.

The EchoSmart sensors also provide all signal control, enhancement and interpretation, and determine the final process measurement, whilst communicating with the EchoSmart Controller via digital communication. This offers greater flexibility in equipment configuration options, enhanced communication capabilities and reduced installation costs.

Bespoke engineered solutions

In addition, ATi utilises its engineering expertise to provide bespoke engineered solutions to suit individual site requirements. This includes various bracketry solutions designed to ensure the EchoSmart equipment does not impede the settlement tank bridge walkway, in line with water utility guidelines, along with robust enclosures to house the controller. This allows for smart, accurate, networked systems that meet regulatory compliance, are simple to install and operate.

The EchoSmart is installed on final settlement tank bridges and communication can be achieved through hard-wired connections or a more bespoke radio-link network, eliminating the need for costly installation. For the radio-link network, a radio is placed on each tank, along with a base station that is wired directly to the site`s programmable logic controller (PLC) in the Instrumentation, Control and Automation section of the Motor Control Centre, providing a useful ‘mimic’ picture on the site’s SCADA.

Flexible, smart networked monitoring

EchoSmart can be used for a wide range of applications and industries, such as sludge thickeners in wastewater, primary or final settlement tanks, and also within the clean water treatment process, including clarifiers on water treatment works. It is adaptable and can be programmed to suit various shapes and tank sizes.

There are also options available for a variety of installation requirements, including a remote or local controller, a stand-alone system, or alternatively a network of up to 16 sensors added to one controller. The system comes standard with analogue and digital outputs, as well as Modbus, but other digital communications can be attained if required.

With automatic initialisation for easy start-up, adaptive algorithms in each sensor for uninterrupted operation, EchoSmart offers the ultimate in installation and networked flexibility, providing an advanced yet user friendly solution, offering cost effective, trouble-free and reliable sludge blanket measurement.

Featured Article

Delivering cost-effective solutions with FilterSmart & EchoSmart

The Punta Gorda WTP is a 10MGD surface drinking water facility located just east of Punta Gorda Florida…

ReadA team of experts, ready to help

A global company with a caring culture. We have a team of experts on hand to help with any product or support query you may have. Contact us and experience ATi’s exemplary customer support.

Get in touch

Click here to see US contact details

Click here to see US contact details  Click here to see UK contact details

Click here to see UK contact details